|

The Meal Floor

Go down the ladder from the stone floor and you come to the meal floor. This is so called because the wholemeal from the stones arrives here down chutes from the millstones above, and falls into the bins where it can cool, fill sacks ready to take away, or be hoisted up to the bin floor to put through the dresser. Go down the ladder from the stone floor and you come to the meal floor. This is so called because the wholemeal from the stones arrives here down chutes from the millstones above, and falls into the bins where it can cool, fill sacks ready to take away, or be hoisted up to the bin floor to put through the dresser.

Look above your head - you can see the great spur wheel, with its wooden teeth, which are made of hornbeam. It drives the millstones through the small gears, known as stone nuts, which can be raised to disengage them when the stones are not in use.

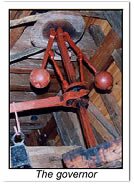

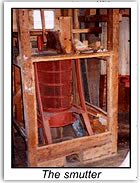

Here you can also see the governor,  which has two iron balls which swing out by centrifugal force as they turn, operating a series of levers which alter the gap between the stones. As the mill speeds up, the governor will reduce the gap, counteracting the tendency of the runner stone to rise up as it runs faster, and ensuring that the quality of the flour remains constant. If the mill is working, you will see the warm meal as it comes out from the end of the chute into the meal bin. which has two iron balls which swing out by centrifugal force as they turn, operating a series of levers which alter the gap between the stones. As the mill speeds up, the governor will reduce the gap, counteracting the tendency of the runner stone to rise up as it runs faster, and ensuring that the quality of the flour remains constant. If the mill is working, you will see the warm meal as it comes out from the end of the chute into the meal bin.  The miller feels this between his thumb and fingers, in order to test the quality of the flour he is producing, and will make adjustments if it is not entirely to his liking. To one side of this floor is the smutter, for removing the black spots of smut, a fungus disease which may grow on wheat grains if they get damp. Above this is a sieve for getting rid of foreign bodies like grass, straw and poppy seeds from the grain. You can also see the big pulley, which brings the drive up to this floor of the mill from the engine below. The miller feels this between his thumb and fingers, in order to test the quality of the flour he is producing, and will make adjustments if it is not entirely to his liking. To one side of this floor is the smutter, for removing the black spots of smut, a fungus disease which may grow on wheat grains if they get damp. Above this is a sieve for getting rid of foreign bodies like grass, straw and poppy seeds from the grain. You can also see the big pulley, which brings the drive up to this floor of the mill from the engine below.

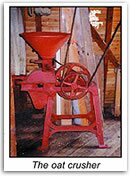

To the right of the smutter is the oat crusher, which was used for producing crushed oats for animal feed. There is also a hand quern - a small pair of hand operated millstones from India, which can be turned by visitors so that they can see for themselves how they work, and produce flour. Querns like this are still made, and are still in use in many parts of the world.

The Stage

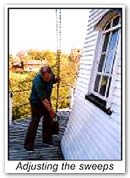

Now, take a walk round the stage outside. Take care, though, if the Mill is working,  as the sweeps come right down close to the stage. You will see the brake rope hanging down the back of the Mill, alongside the chain with the weight on it, which works the shutters of the sweeps. Look up at the back of the cap, where the fantail carriage sticks out. Under it, near the Mill, you will be able to see the worm, which drives the cap round. Even if the fantail is working, you will not see the cap moving from here, as it travels far too slowly - it takes at least three-quarters of an hour to do a half turn, with the fan going flat out! as the sweeps come right down close to the stage. You will see the brake rope hanging down the back of the Mill, alongside the chain with the weight on it, which works the shutters of the sweeps. Look up at the back of the cap, where the fantail carriage sticks out. Under it, near the Mill, you will be able to see the worm, which drives the cap round. Even if the fantail is working, you will not see the cap moving from here, as it travels far too slowly - it takes at least three-quarters of an hour to do a half turn, with the fan going flat out!

When you have seen enough on the stage, you can go back into the Mill, and down one more flight of steps. You arrive on the first floor, with its loading door, which was used to load and unload sacks from the carts which came to the Mill. At the opposite side of this floor are three compartments, now used only for storage. These served to contain the different grades of animal feeds which were produced from the three-layer jog-scry, or sieve above. This floor is now used for showing a video of the mill. If you did not see this before you went up, you may care to stop here and see it after your tour, as it should help you to understand the workings of the Mill more fully.

Leaving the first floor by the stairway, you once more arrive at the ground floor. Look at the two big millstones which are leaning against the wall. You can clearly see the differences between the two types of stones - the one-piece peak stone from Derbyshire, and the French burr, quarried near Paris, which is made out of separate pieces of stone, cemented together and bound with an iron band.

The metal bins on this floor are used for storing grain before it is raised by the sack hoist to feed into the millstones. The metal bins on this floor are used for storing grain before it is raised by the sack hoist to feed into the millstones.

If you now cross the ground floor to the door at the rear of the mill, you can go through to the engine shed, where you can see the engine, which will drive the mill on calm days. This engine, which came from a farm in West Chiltington, produces 17 horsepower, which is ample to drive a pair of millstones and other machinery on the floors above.

The far end of the engine shed was used as the shop, where you have in the past been able to buy souvenirs of your visit to Shipley Windmill. Originally the engine shed housed a steam engine which drove the mill, but this was scrapped in the 1920s, when the mill ceased commercial work.

Next Page >>

|